Flooring counts as matter of course. It is in permanent contact with us and vice versa. It is the foundation of your point of view, accounts for continuity and reassurance. In this project the focus was ambiguous: on the one hand a free interpretation of floor on the other a conventionel draft.

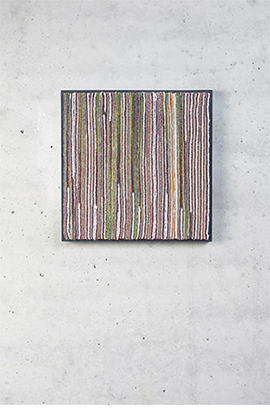

I. feltparquet

This floor, carried by a recycling concept, was developed together with Svenja Bernhold: the feltparquet. What happens to all those fabrics with slight defects that cannot be sold? Everyday metres of fabric are manufactured, stored away and in the end never to be used. Our plan was to make a flooring you do not have to produce new materials for. Using as few additives as possible within the process of recycling we wanted to be able to use all kinds of raw material. While experimenting, glueing, sewing and felting proved to be very suitable techniques for floor-construction. Felting in particular forms a solid mechanic compound of the different fabrics without any additives at all, simplifying the even further process of recycling within the fabric ́s cycle. The creation of a new product saves ressources to the extreme. Layering, carving and cutting allow new surfaces, different durability and qualities. New floorings in parquet- or tile-look can be created through this technique. Precise lasercutting and processing allows a huge variety of patterns.

A project in cooperation with Xentrys and Carpet Concept.

The „first floor“ was developed both conventional and textile-wise in collaboration with „Xentrys“, a yarn manufacturer, and the Carpet weaving company Carpet Concept. Material development started off from the scratch with the creation of a variety of yarns. Those were utilised in tufting samples as well as in realizing a patternsample for a woven carpet.